Secondary services

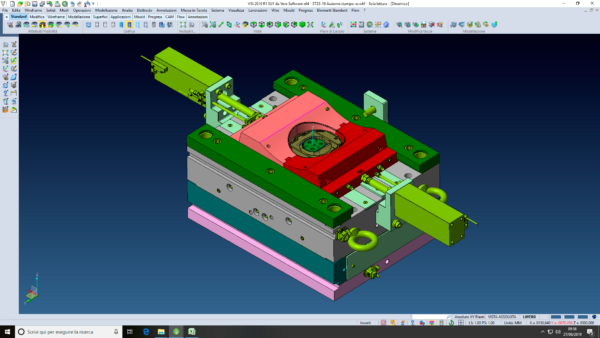

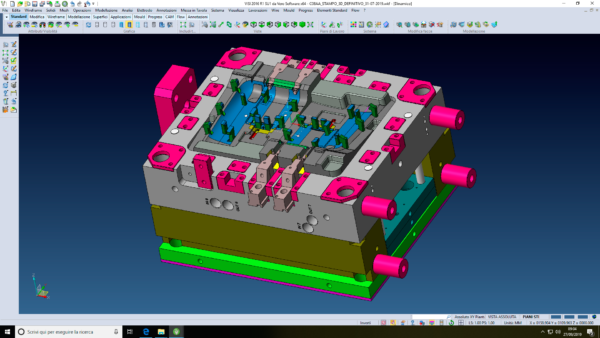

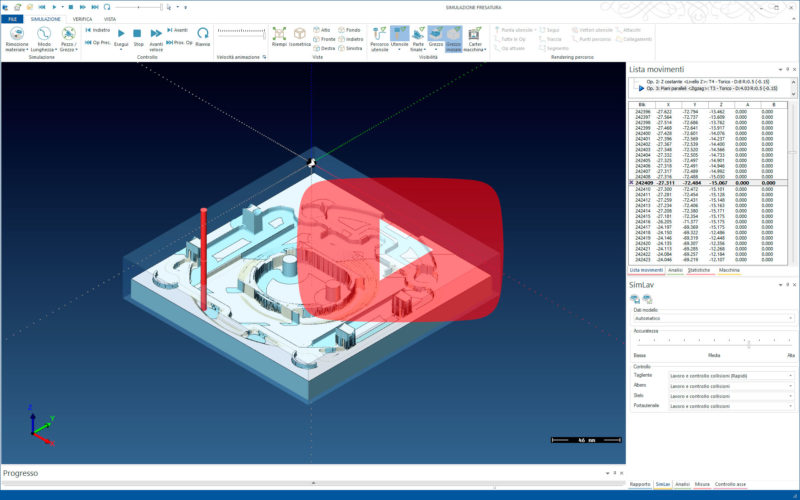

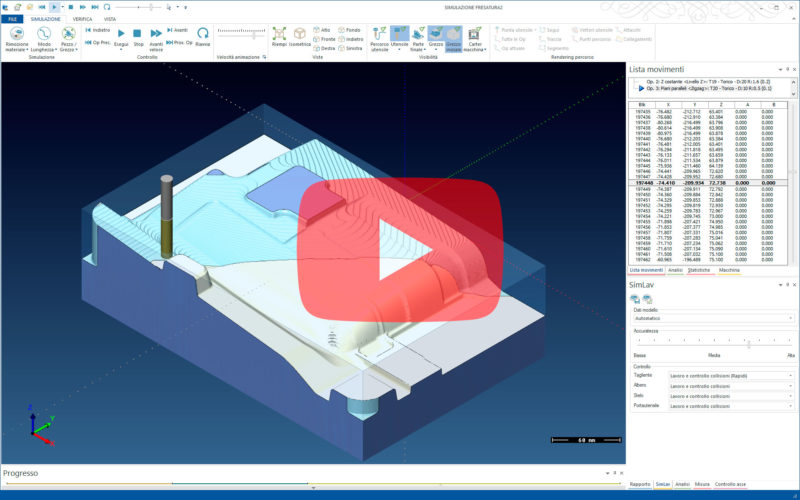

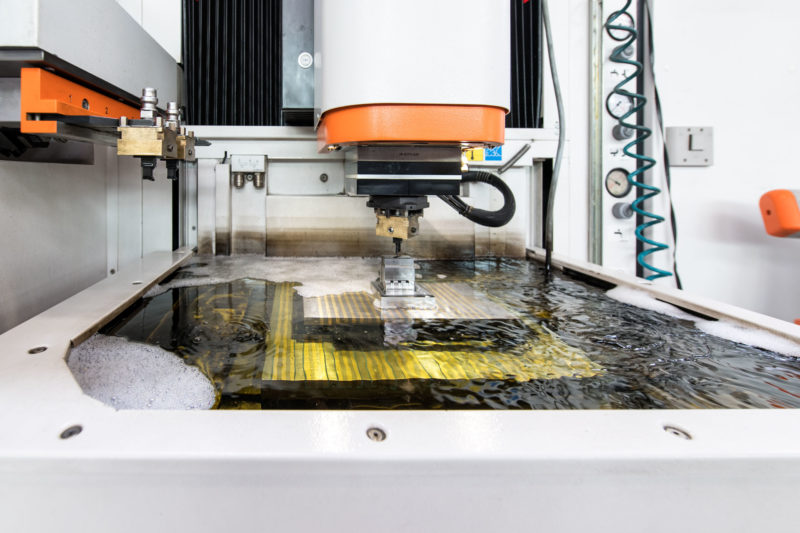

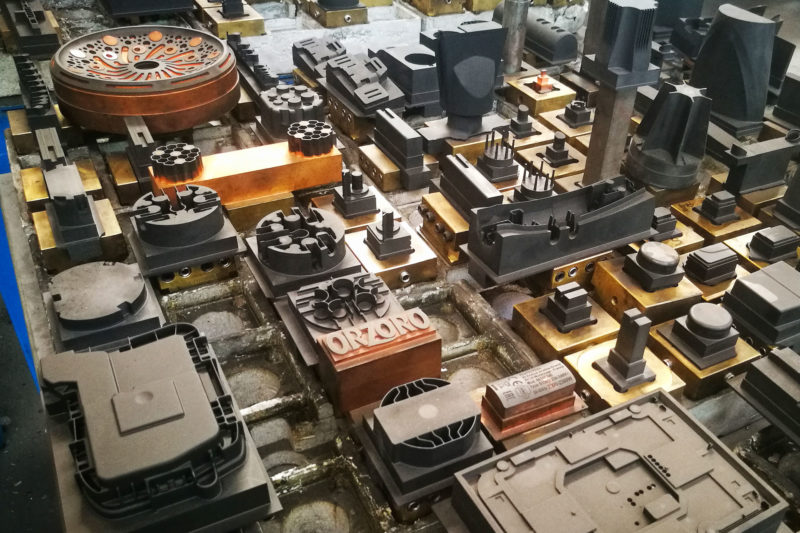

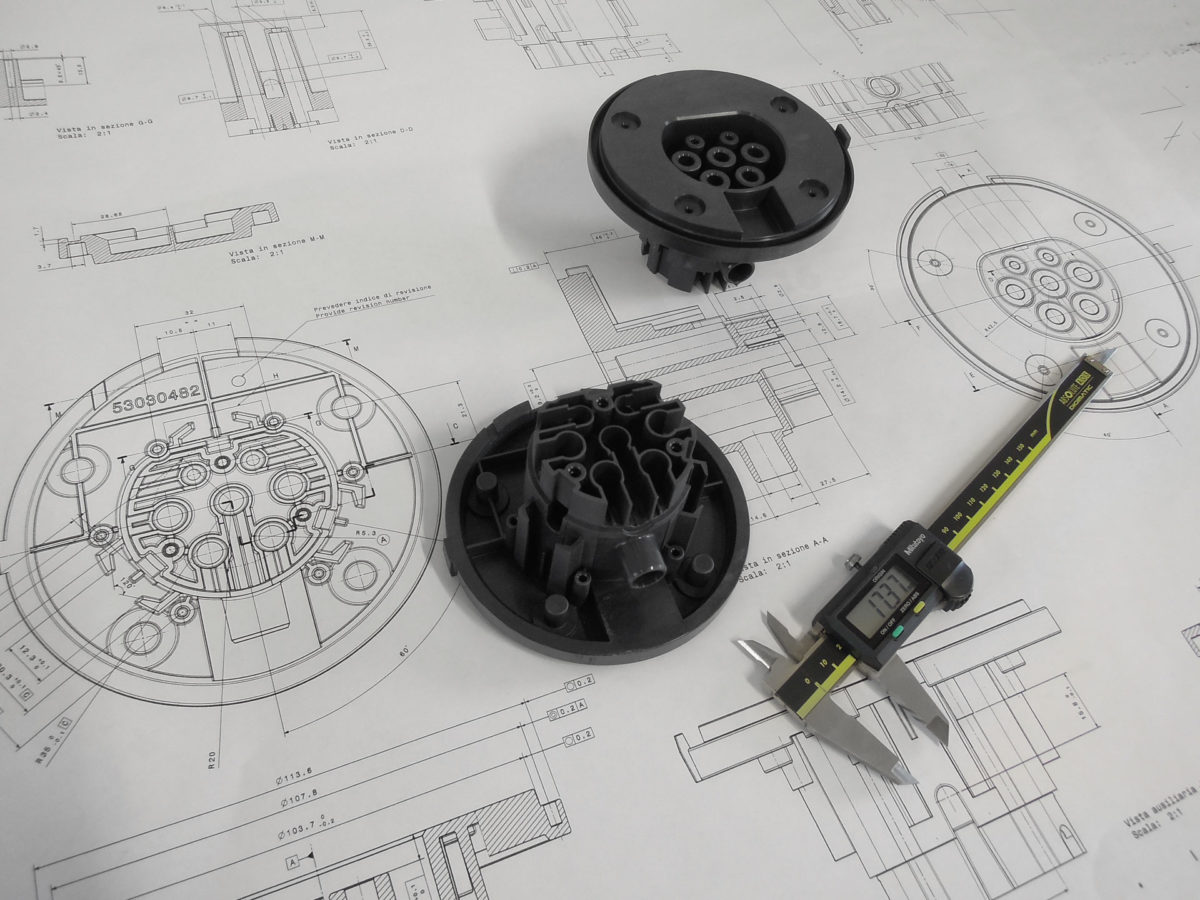

MOULD MAINTENANCE AND MODIFICATION

SCREEN PRINTING

CHROME-PLATING

PACKAGING

MOULD MAINTENANCE AND MODIFICATION

SCREEN PRINTING

CHROME-PLATING

PACKAGING

CONTAC US

Do you need any information about moulding? Fill out this form to get in touch.